Access Denied

IMPORTANT! If you’re a store owner, please make sure you have Customer accounts enabled in your Store Admin, as you have customer based locks set up with EasyLockdown app. Enable Customer Accounts

Kategorie: Tischkultur

-

Espresso-Tasse | 224 | 0,05 l | aussen weiss biskuit und innen glasiert

Normaler Preis 80,00 EuroNormaler PreisGrundpreis / pro -

Ausverkauft

AusverkauftEspresso-Tasse | 196/3a | 2452 | schwarze Zacken

Normaler Preis 560,00 EuroNormaler PreisGrundpreis / pro -

Espresso-Tasse | 88/3a | 0,06 l | weiss

Normaler Preis 320,00 EuroNormaler PreisGrundpreis / pro -

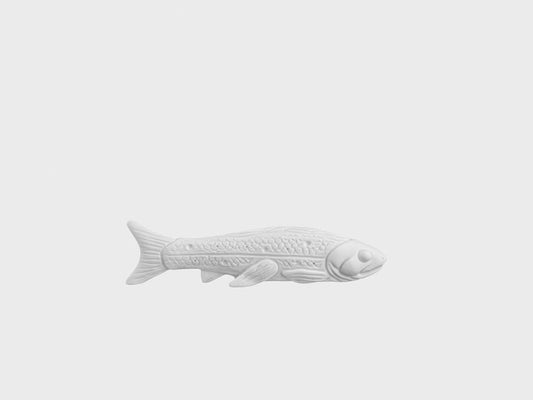

Messerbänkchen Fisch | 2018 | weiss biskuit

Normaler Preis 180,00 EuroNormaler PreisGrundpreis / pro -

Schnecke Salz-und Peffer Set | 1707b/1707a | 2588L | aussen weiss biskuit und innen Inglasur Fond ro

Normaler Preis 330,00 EuroNormaler PreisGrundpreis / pro -

Mondschneckenschale |34 cm | 1703/3 | 2588L | aussen weiss biskuit und innen Inglasur Fond Muschelro

Normaler Preis 2.160,00 EuroNormaler PreisGrundpreis / pro -

Platzteller | 31 cm | 1818 | 2645 | Épure |handbemalt Bleistift Skizzen

Normaler Preis 470,00 EuroNormaler PreisGrundpreis / pro -

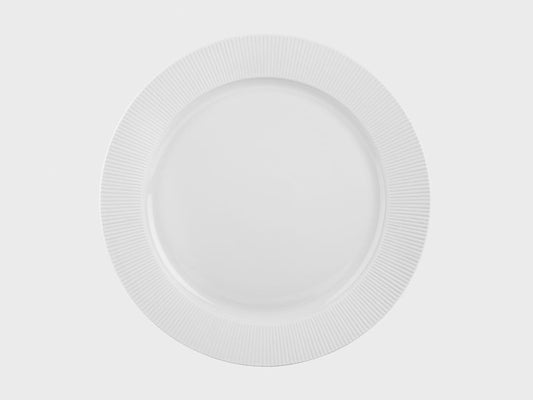

Platzteller | 32 cm | weiss biskuit glasiert

Normaler Preis 460,00 EuroNormaler PreisGrundpreis / pro -

Gourmetteller flach 32 cm

Normaler Preis 380,00 EuroNormaler PreisGrundpreis / pro -

Gänseei Vase | 10 cm | 1716/0 | Vogelei blau biskuit glasiert

Normaler Preis 120,00 EuroNormaler PreisGrundpreis / pro -

Gänseei Vase | 10 cm | 1716/0 | Platin

Normaler Preis 350,00 EuroNormaler PreisGrundpreis / pro -

Gänseei Vase | 10 cm | 1716/0 | Mattgold

Normaler Preis 350,00 EuroNormaler PreisGrundpreis / pro -

Becher concav | 9 cm | 0,20 l | 1719 | weiss biskuit und innen glasiert

Normaler Preis 160,00 EuroNormaler PreisGrundpreis / pro -

Becher convex | 9 cm | 0,23 l | 1718 | weiss biskuit und innen glasiert

Normaler Preis 160,00 EuroNormaler PreisGrundpreis / pro -

Becher | 1966 hoch | weiss biskuit glasiert

Normaler Preis 160,00 EuroNormaler PreisGrundpreis / pro -

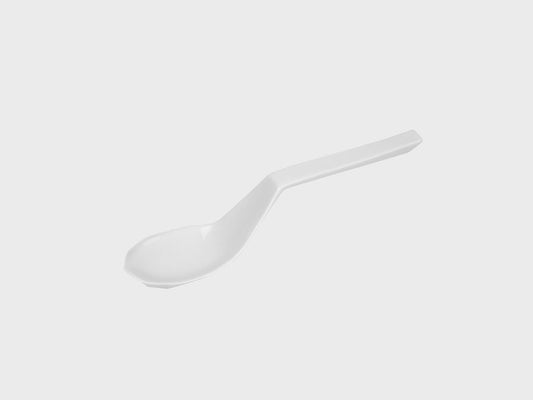

Löffel | 1818 | aussen weiss biskuit und innen glasiert

Normaler Preis 140,00 EuroNormaler PreisGrundpreis / pro -

Korallenlöffel | 15 cm | 1714 | 2588K | Korallefarbiger Fond glasiert

Normaler Preis 280,00 EuroNormaler PreisGrundpreis / pro -

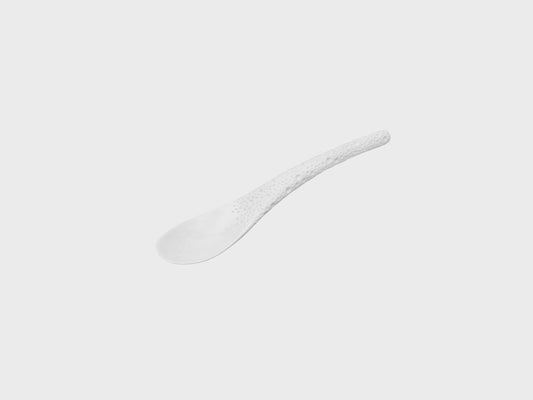

Korallenlöffel | 14,5 cm | 1713 | weiss biskuit glasiert

Normaler Preis 140,00 EuroNormaler PreisGrundpreis / pro -

Wasserkrug | 2012 | 1,0 l | 2657 | Holzmaserhenkel auf biskuit glasiert

Normaler Preis 810,00 EuroNormaler PreisGrundpreis / pro -

Ausverkauft

AusverkauftMilchkanne | 2 | 0,16 l | 2452 schwarze Zacken

Normaler Preis 580,00 EuroNormaler PreisGrundpreis / pro -

Maus Karl der Athlet | 2266bQ | 9 cm | weiss biskuit

Normaler Preis 240,00 EuroNormaler PreisGrundpreis / pro -

Maus Karl der Geschenkbote | 2266Q | 9 cm | weiss biskuit

Normaler Preis 240,00 EuroNormaler PreisGrundpreis / pro -

Maus Karl der Strippenzieher | 2266aQ | 9 cm | weiss biskuit

Normaler Preis 240,00 EuroNormaler PreisGrundpreis / pro -

Schale | 24 cm | 1818/6 | aussen weiss biskuit und innen glasiert

Normaler Preis 710,00 EuroNormaler PreisGrundpreis / pro

Invalid password

Enter